Last week, we spoke about how in-house and just-in-time fulfillment granted you complete control over your fulfillment process. This week, we’re going on the other end of the spectrum with outsourced fulfillment.

Fulfillment can be quite the drag. It’s complicated, we all know this. So why not pay someone else to do it? That’s the gist of outsourced fulfillment, and we’re about to get into the upsides and downsides of it, as well as expenses to expect.

And, as a heads up, outsourced fulfillment can get mighty complicated. This 2,000+ word post only scratches the surface on how it functions and all of the costs involved, but it should give you an idea of how the wheels turn.

Figuring Out Outsourced Fulfillment

Outsourced fulfillment is about taking your inventory and shipping operations, and moving them to a privately owned warehouse that stores product, receives, packs, and ships your orders. You’re still dealing with buying up inventory from suppliers, but you won’t be getting your hands dirty with the grind of managing inventory and getting products to the customer.

You’re about to see the word 3PL a lot, and it stands for third-party logistics provider. Straightforwardly put, a 3PL is the service that stores and ships your orders. They’re the “outsourced fulfiller,” so to speak. You send them your inventory, they keep your product safe and sound in their warehouse, and they pluck products from storage, package them, and ship them off once a customer’s order comes their way.

Source of Its Appeal

Merchants outsource fulfillment because they’d rather have someone else handling the administrative task of fulfillment. Maybe they just despise it, maybe their order volume is just too enormous for them to do it themselves (a good problem to have), or maybe they love the efficiency of a 3PL. In any case, they’re outsourcing the entire process.

And that’s the ultimate benefit of the model. Because you won’t be dealing with fulfillment, you’ll have more time for just-as-important matters, like product and content marketing, conversion optimizing, or building a brand strategy, while your 3PL expertly stores and ships.

Another bottom-line-friendly perk is the shipping rates you’ll be able to access. Because a 3PL is fulfilling a large quantity of orders from the many businesses using it, it’s able to negotiate discounted rates with shipping carriers that those businesses can take advantage of.

Downsides

There are some major tradeoffs to the model, though. Compared to in-house or just-in-time fulfillment, you won’t have nearly as much control over your fulfillment — you’re outsourcing it, after all. You’ve added a third-party to your business that does things their own way, and that erosion of control can have some repercussions:

- Lack of TLC — because fulfillment is not in your control, you may lose the opportunity to personalize and brand orders. That said, some 3PLs are willing to accept and fulfilling with branded materials that you send their way. Just ask if it’s possible.

- Lack of visibility into inventory — one of the more uncomfortable parts to outsourced fulfillment is that your largest investment, your inventory, is far away from you. You’re leaving it in a 3PL’s possession, and you must have a way of getting accurate inventory counts (less you risk a stockout), as well as a way to actually send them orders to be fulfilled.

- Returns management — if fulfilling in-house, a return gets sent back to your HQ where it was shipped from. But with outsourced, it goes back to your 3PL, creating a barrier between you and a dissatisfied customer that prevents a clear line of communication on what exactly went wrong.

- Costs — outsourced fulfillment is not for everyone. It can get pricey; with every order they fulfill, a slice of that revenue will go towards paying them. Not to mention they charge storage fees, you most likely will pay for shipping, and.. well, we’ll get to the costs soon.

All of these downsides aside, once your outsourced model is set up, your fulfillment process should run like clockwork while you go about growing your business instead of maintaining it. But setting it up and dealing with the costs are, without a doubt, the hardest parts.

The Costs

Prepare yourself, we’re about to get into the nitty gritty of how 3PLs work with and charge e-retailers.

Because you’re bringing that 3PL into the mix, your fulfillment process is definitely going to get a little more complex and expensive. You’re going to want to ask yourself some questions before pursuing it:

- Is order volume consistent — the costs we’re about to get into will largely be based on how much inventory you want stored, and, by extension, how much demand you’ll need fulfilled. A consistent order volume will keep costs manageable and predictable.

- Are products viable for outsourced fulfillment — a 3PL is all about efficiency; if your products are perishable, fragile, handmade, or personalized, outsourced fulfillment may be difficult. Non-perishable, bulk products that are easily stored are preferable.

- How easy is it to integrate sales channels with your 3PL providers — a 3PL must have orders routed to them. Unless you plan on manually sending them orders by email, fax, or phone, you’ll need to build a software integration between your sales channels and the 3PL so orders automatically head their way and information is relayed back.

As far as actual 3PLs for you to check out, here are some providers:

The ones above will give you a good idea of how 3PLs look, and by no means are they the only ones out there. Every provider will have their own pros and cons, and you’ll need to research them each to ensure that they meet your needs. For a deeper dive and cost comparison on various services, check out this order fulfillment guide by Fit Small Business.

It’s also worth pointing out that each provider’s pricing plan is different. The following are general costs to expect whenever you work with a 3PL. Get ready — there are quite a few!

Set-Up Fees

As mentioned earlier, one of the largest issues with outsourced fulfillment is the lack of visibility into your inventory. Product isn’t at arms-length from you. It’s tucked away in a third-party controlled warehouse that needs to be made aware of orders if it’s to do its job.

All of the pieces of your fulfillment machine need to work and communicate seamlessly with one another. That’s where a 3PL’s set-up fee come in, and it can get pricey, ranging from the hundreds to the thousands.

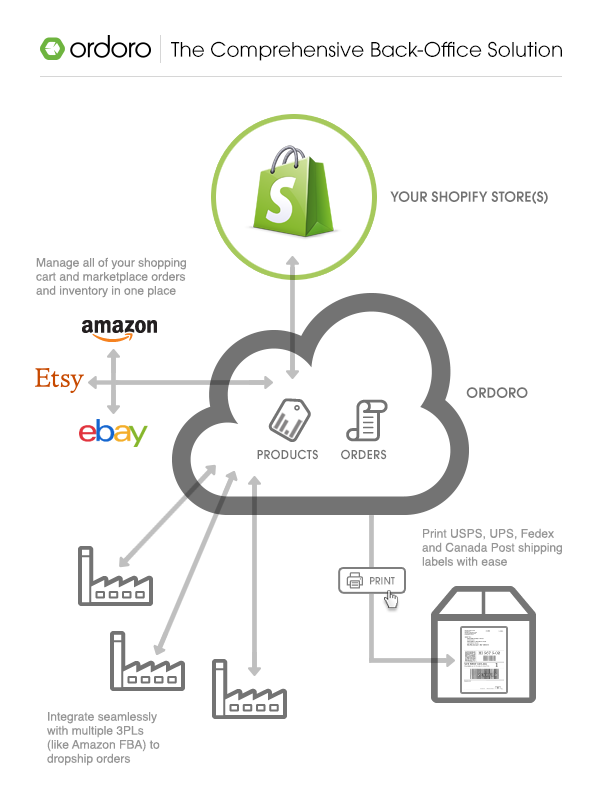

The set-up fee is what’s charged by the 3PL to build an integration that communicates with a sales channel. Whenever an order is made on a sales channel, it communicates with the 3PL through that integration, automatically alerting it to a ready-to-be-fulfilled order. Your 3PL then fulfills the order, and relays other information, like tracking info, back to the sales channel for you to check out.

Larger 3PLs likely have integrations with common sales channels, like Shopify or Amazon, so they might be able to waive the set-up fee unless you need the 3PL to be integrated with anything unique, like a home-grown cart or new app. It’s also possible not to have the 3PL do it, but to hire a developer to build the integration.

But what complicates matters further is the fact that e-retailers are finding themselves forced to move multichannel as ecommerce evolves into a purchase process with touchpoints on multiple channels. Whether it’s an order made on social media, a merchant’s self-hosted storefront, or on a marketplace like Amazon, a variety of channels are connected to the same inventory that’s stored in one place far away from you.

But what complicates matters further is the fact that e-retailers are finding themselves forced to move multichannel as ecommerce evolves into a purchase process with touchpoints on multiple channels. Whether it’s an order made on social media, a merchant’s self-hosted storefront, or on a marketplace like Amazon, a variety of channels are connected to the same inventory that’s stored in one place far away from you.

Order management systems can function as a central hub to keep track of orders and inventory. Here’s how it works: sales channels integrate with the order management system so that the merchant can (you guessed it) manage all of their orders from every sales channel in one place. The 3PL then integrates with the order management system, accessing and communicating with all of the already-integrated sales channels.

But let’s not run away on a tangent. Back to the costs.

Storage Fees

Just as you might rent storage with in-house fulfillment, you’ll also be paying for storage with 3PLs. They’ll have storage fees centered around how much space your stored product will take up, typically charging based on how many pallets or footage you’ll need, which is usually measured in square or cubic feet.

It works like so: you take the dimensions of your packaged, stored product and determine how many of them can fit on a pallet or within a measured space (a 3PL’s pricing will determine which measurement they charge for, pallet or footage). They’ll then charge a set amount for that space, like $0.50 per cubic foot or $1 per pallet. Usually on a monthly basis, they’ll do an inventory check to determine how much space you’ve taken up. Then they bill you.

Although it isn’t technically a cost, some 3PLs will require a storage minimum. Before working with you to store and fulfill products, they may demand that you store a certain amount with them for your business to be worthwhile. For instance, if the amount you want stored doesn’t quite meet a pallet’s worth, the 3PL will still store it, but they’ll charge you for the minimum pallet’s worth.

And the longer your inventory is stored with a 3PL, the more likely they’ll up their fees, usually dubbing them along the lines of “long-term storage fees.” It’s exactly as it sounds — the 3PL charges long-term storage fees in addition to their normal storage fee if a product is collecting dust for longer than six months or so. It’s a way to ensure product doesn’t linger for too long.

Picking and Packing Fees

Whether it’s by robots or (in most cases) humans, something must process orders, and that means picking products off shelves or from boxes, and packaging them for fulfillment. 3PLs charge fees for this, called pick and pack fees, on a per order or per item basis.

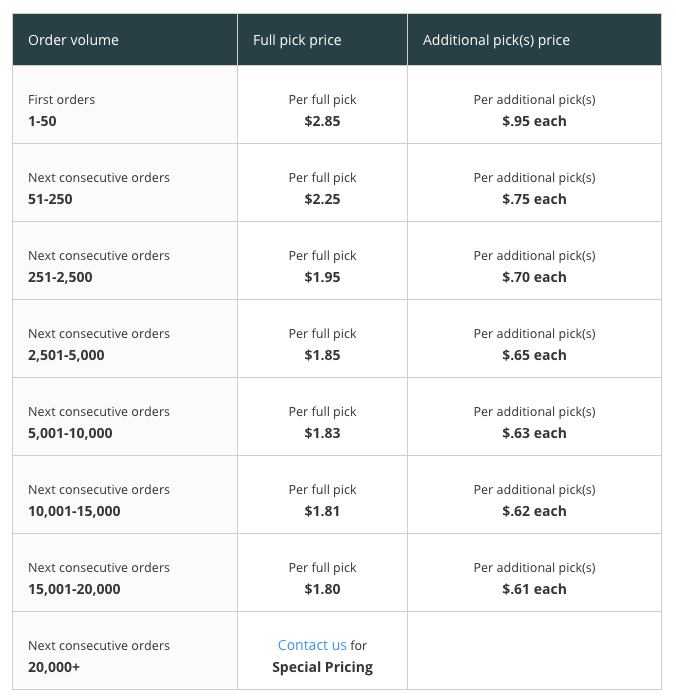

Some 3PLs are interested in high volume merchants, so they offer scaled discounts to those who store and fulfill a larger quantity of orders. Here’s a look at how Shipwire, a popular 3PL, charges:

Pick and pack fees sometimes bundle other expenses as well. A 3PL can choose to charge a slightly higher pick and pack fee that incorporates packaging material expenses, for example. Or they can charge you separately for the materials — just be sure to check their pricing structure.

Order and Weight Handling Fees

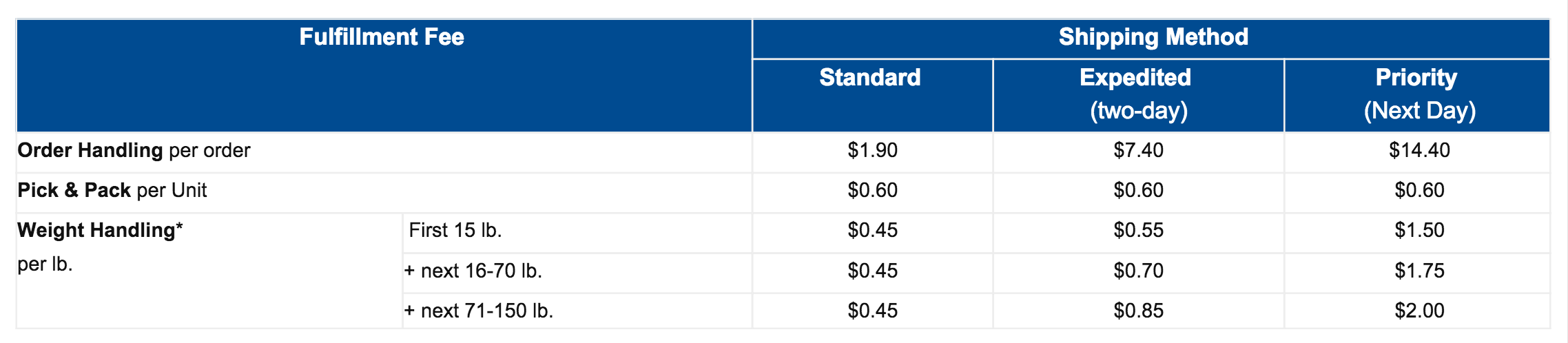

In addition to that pick and pack fee, a 3PL may also tack on order or weight handling fees as they process orders for fulfillment. These charges are usually dependent on (obviously) the order’s weight, as well as how a 3PL ships the product.

Here’s a good example illustrating how order, weight, and pick and pack fees work together. With Fulfillment By Amazon (FBA) — a popular service used by many merchants — there are a few factors that go into the total fee of processing an order:

Shipping Fees

A no brainer, your 3PL has to ship your products, and — depending on the service — you’ll be paying for the shipping. As was mentioned earlier, the good news is that you’ll have access to cheaper shipping rates that 3PLs are able to negotiate thanks to the high order volume they’re pumping out.

Receiving Fees

Another thing to keep in mind is the fact that you’ll need to ship your products to your 3PL’s actual warehouse for them to sort out and store. Often referred to as a receiving fee, some 3PLs will charge you for receiving scheduled resupplies, setting up storage, and reporting inventory levels. The cost can be based on SKU quantity or on an hourly basis.

Returns Processing Fees

Some 3PLs will charge you if a return occurs. A 3PL will take that return and process it, inspecting the packaging and product, collecting any sort of feedback, and alerting the seller of the return. After all of that, it’s usually up to the merchant to decide whether they want the return sent to them for further inspection, or if they want it restocked or thrown away. For all of that work, the 3PL will normally charge a per order fee.

An Outlook On Outsourced Fulfillment

It’s daunting, isn’t it? There are so many potential charges just to get an order out of a warehouse door to the customer’s door. To make matters a little worse, these prices have the potential to rise as more and more merchants join the ecommerce fray, looking for 3PLs to do the work for them. The less space, the more costly it’ll get.

This isn’t to discourage you from considering outsourced fulfillment, because it comes with that serious advantage of not having to handle fulfillment. Just be sure you understand exactly how much of a slice of revenue your 3PL is going to take from every order they fulfill, as well as the other charges, like storage and receiving fees, that come with stocking product there.

Margins and expected order volume are the key for forecasting whether outsourced fulfillment is feasible for you. There’s no average order volume universally understood to mark when it’s time to outsource — it depends on too many business-specific factors, like reliability of demand, product margins, and other costs like overhead or marketing-related expenses.

Instead, you need to confidently forecast your demand, and, most importantly, intimately understand the pricing of your 3PL to ensure that your margins can take it. Selecting a 3PL with a pricing structure that works with you and your product is an absolute must.

Mix It Up

Yes, it can get quite expensive to have an outsourced fulfillment model. But so can in-house at a certain order volume. As your demand escalates, you’ll need more product, more space, and more help. That means greater costs from renting warehouse space and hiring employees. For some businesses, it’s more efficient, if not more cost-effective, to outsource their fulfillment.

And it isn’t like you must use a single model for your entire business. No business must be exclusively in-house or outsourced. It depends on your product and demand. Fulfilling a specific product through a 3PL while fulfilling the rest of your product catalog in-house is a definite possibility.

For instance, if you carry small, compact products that sell steadily with slim margins like some sort of CD, it would be pretty easy to store them in your own warehouse or your own place, fulfilling them in small parcels whenever orders are made.

On the other hand, let’s say you also sell rustic-looking record players that are relatively large-sized, have bigger margins, and a larger demand. Such a product requires more storage space, more time to fulfill, and you have more room in your margins for 3PL’s to take a cut. Perhaps they’d be better off with outsourced fulfillment — let the pros store and handle the product.

But how about we just get rid of inventory? That’s at the core of every fulfillment model, and it’s the major cause of all the intricacies of fulfillment. Outsourced fulfillment, for some, just isn’t hands-off enough. Dropshipping, however, completely meets that criteria, and we’ll cover it in the coming weeks.