Over the past few years, ecommerce has rapidly changed, adjusting to consumers that are increasingly headed online to buy. And as the online selling game reacts to changing behavior, fulfillment — storing and shipping your product — inevitably does the same.

The holiday season is pretty much finished, and now it’s time to look to this year. There are plenty of fulfillment trends to keep an eye on, each of which is driven by growth.

Costs Are Going Up

Every year, it seems like shipping carriers make a deal to tick up their shipping rates. It won’t change next year — UPS upped rates right after Christmas, FedEx did the same after New Years, and USPS is planning a bump in late January.

It isn’t too hard to understand why they’re going up. Higher order volumes mean more shipments hitting the road, which means higher costs for carriers that must be offset by a rise in pricing. When price increases begin to fall off is anyone’s guess, but you can be sure that as long as ecommerce continues growing, shipping rates will as well.

Multichannel On the Rise

All that’s needed for ecommerce is an internet connection, and there are a plethora of ways to sell online. With traffic flowing from a variety of sources, merchants, now more than ever, are making sales on multiple channels, whether it’s a marketplace like Amazon or hosted cart like Shopify.

That’s not going away anytime soon. Merchants will likely continue getting their businesses in front of consumers by as many platforms as possible. But the word multichannel applies to logistics, too, and merchants are beginning to incorporate a variety of supply-side channels into their businesses. As e-retailers bring different products to their catalog, their fulfillment channels diversify.

For instance, some merchants begin working with dropshippers to expand their product selection, creating another fulfillment channel to attend to. Some tackle fulfillment in multiple ways depending on product — fulfilling some items, particularly small or lightweight ones, in-house while using third-party logistics providers (3PLs, we’ll get to them next) to store and ship larger, more costly ones.

Needless to say, both the front end and back end of online businesses are getting more channels.

Demand For 3PLs

For all the reasons mentioned above, third-party logistics providers are looking mighty attractive. Dubbed 3PLs, they store and ship merchants’ products, and more are likely to pop up over the coming year with more merchants popping in for business.

The major deterrence to 3PLs is the cost of working with them. Having someone else store and ship orders comes at a price, and not every e-retailer is willing to pay up. But ever-rising shipping expenses and order volumes are making them look a little more attractive.

Because they tend to deal with many orders, 3PLs are able to negotiate cheaper rates with shipping providers that merchants have a harder time accessing. And, depending on order volume, storing and shipping product through 3PLs can become more effective in terms of both costs and time.

Multichannel moves also play into 3PL demand. As they sell on a few (or several) channels, tracking and aligning inventory can quickly morph into a juggling act for merchants. 3PLs take on that operation themselves — merchants integrate their channels with 3PLs to streamline their process. Once an order comes in, it’s sent directly to the 3PL who fulfills it, adjusts inventory, and sends info back to the merchant.

Fulfillment By Amazon (FBA) is a prime example of the rising interest in 3PLs — demand is so high that they raised their costs during the holiday season to thin the herd of e-retailers using them. On the international scene, eBay recently bolstered its own 3PL shipping service called eBay Global Shipping due to higher demand. Expect that trend to continue.

More Warehouses On the Way

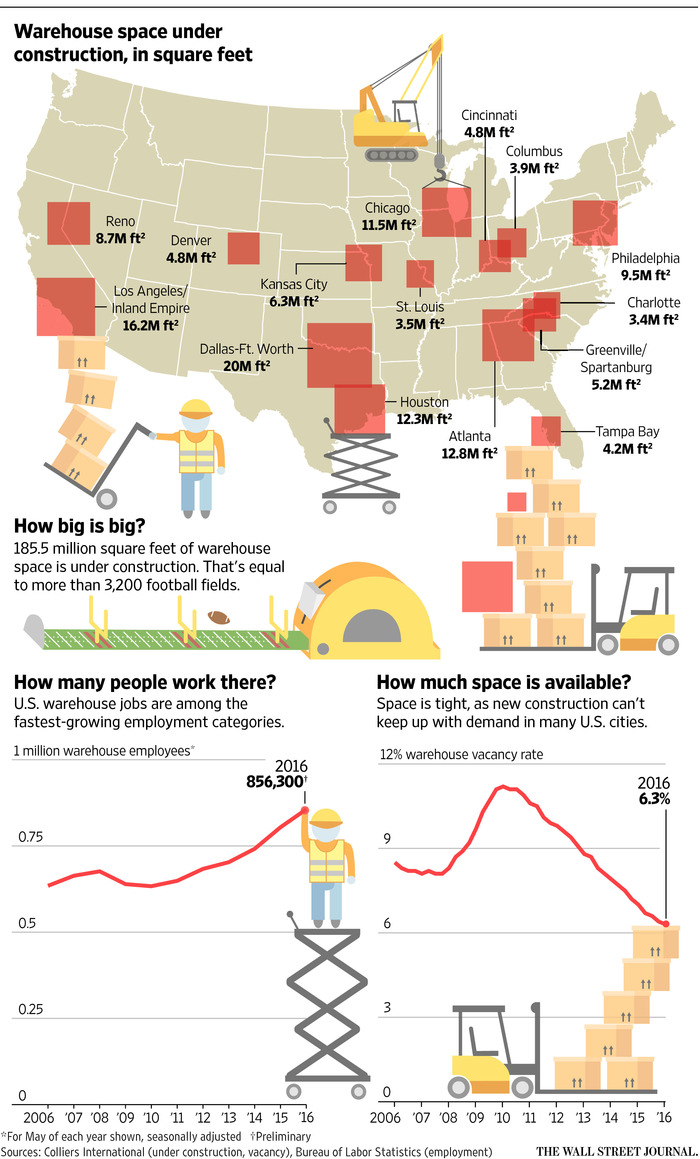

Greater merchant demand for 3PLs means more being built. More warehouses are on the way, and they aren’t being built fast enough — even Amazon, with all its revenue and infrastructure, launched its Seller Fulfilled Prime program in part to use retailers’ own warehouses.

Next year will definitely see more warehouses dotting the landscape, and it’s also worth noting where they’ll be built. To cut down on shipping costs and delivery times, they’re strategically arriving near population centers:

Not only that, some are getting equipped with automation tools. From robots that separate and load cases of products to robots that arrange, organize, and pick product from storage, utilizing automation to cut down on expenses while speeding up operations is beginning to spread.

Packaging Becomes a Bigger Deal

For retailers fulfilling orders themselves, packaging offers a unique opportunity that’s likely to gain more attention in the coming year. At the end of the purchase experience is an unboxing one, and consumers are keen on unboxing for a variety of reasons — it caps the purchase process with excitement, and, through unboxing videos, it offers a chance to inspect the product before buying.

Studies show that packaging does in fact have significant impact on how a customer perceives both product and brand. Just check these stats pulled from a study by distributor DotCom Distribution:

- 68% of online consumers believe that branded packaging suggests a premium brand

- 61% feel that branded packaging added excitement upon receiving the order

- 44% think that branding reinforces the price of a product

At the end of the day, branded packaging is an opportunity for e-retailers to reinforce their brand, justify higher pricing, and differentiate themselves from what’s otherwise a boring cardboard experience. Don’t be surprised to see more colorful, unique, and non-cardboard orders hitting the streets.